Polytex ModulePro® Cotton Wrap

Trusted in the Cotton Industry for 30 Years

Polytex has been supplying the cotton industry for 30 years. In the late 1990's and throughout the early 2000's Polytex manufactured module covers for the square cotton modules, protecting 1000's of growers cotton from central Queensland and down throughout New South Wales.

As round-module pickers became standard, we identified the need for a competitive, high-quality wrap. We partnered with an established manufacturer, validated the spec in Australian conditions, and have now launched our own ModulePro® wrap, aligned with Australian quality standards and sold internationally.

Get a Fast Quote

Polytex ModulePro® Cotton Wrap

Designed for Australia’s tough cotton picking conditions, the Polytex ModulePro™ Cotton Wrap delivers reliable performance, exceptional durability, and peace of mind from field to gin. Made from high-strength UV-stabilised linear low-density Polyethylene (LLDPE), ModulePro® provides the protection growers demand to maintain cotton quality and minimise losses during storage and transport.

Engineered for Strength & Durability: Polytex ModulePro® cotton wrap is engineered to be highly resistant to tearing, UV degradation, and moisture, providing a weatherproof barrier to protect the cotton. Our wrap utilises a non-tacky base film to prevent the cotton from sticking to the wrap, followed by a structure of tacky film to ensure the module will hold it’s uniformity during transportation and processing.

RFID codes for Accurate Traceability: Four RFID tags are applied to each wrap to allow for identification and tracking through harvesting and throughout the complete process.

Superior UV Protection: Multiple layer film technology with multiple UV inhibitors ensures high strength and protection against UV for durability while in the field.

Trusted by Growers Nationwide: With over 30 years of Australian manufacturing experience, Polytex delivers solutions trusted across the agricultural sector. ModulePro™ continues this legacy by combining material innovation with dependable on-farm performance.

Multi-Layer Technology

Every wrap portion is made of two segments. The integration of these two distinct film variants guarantees that the circular module will maintain its consistency during transportation and handling.

The inner film layers feature distinct non-adhesive properties that prevent cotton fibers from adhering to the wrapping.

The outer layers incorporate a uniquely formulated film that is tacky on one side only.

Radio Frequency Identification (RFID)

Each Wrap includes RFID tags to enable module tracking through harvesting and processing, all integrated with the John Deere On Board Module cotton harvesters’ electronic systems.

UV Protection

Modules wrapped can be left outside up to 6 months. Cotton film can remain intact at -5℃ – 60℃ (23 ℉ – 140 ℉)

Water Protection

Goes over the edge to minimize cotton waste and exposure to rainfall, holding tight round module shoulders.

Hassle-Free Operation

Pre-Cut Portions

Comes in 24 pre-cut portions to prevent plastic fragments

TiteGuard® Edge

Full edge protection with tight shoulders for strength during handling and transport.

Correct Installation Mark

Clearly marked wrap assists in proper installation and application.

Gin Friendly

Easily processed through gins ensuring hassle-free unwrapping and processing.

Sustainability

Cotton wrap material is recyclable and environmentally friendly.

Identification

To enable full traceability, each roll has its own ID number located inside core, and on leading edge of the first wrap.

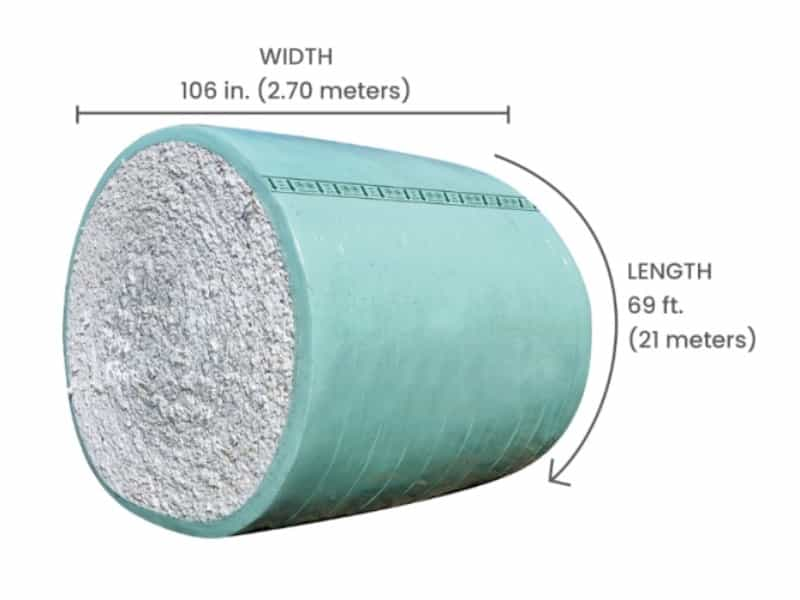

Specifications

Roll Width...................................................8.85 ft / 2.7 m

Individual Sheet Length..........................69 ft / 21 m

Module Weight CP690............................2,041-2,495 kg 4,500-5,500 lb

Module Weight CP770............................2,222-2,676 kg 4,900-5,900 lb

Diameter Up CP690.................................238.8 cm 94 in

Diameter Up CP770..................................244 cm 96 in